🌕This article is about the failure analysis of ceramic capacitors, which may fail in different environments.

1.Influence of humidity on deterioration of electrical parameters

🌝When the temperature in the lost air is too high, the water film condenses on the surface of the capacitor shell, which can reduce the surface insulation resistance of the capacitor. In addition, for semi-dense structure capacitors, moisture can also penetrate into the capacitor medium, which reduces the insulation resistance and insulation ability of the capacitor medium. Therefore, the influence of high temperature and high humidity environment on the deterioration of capacitor parameters is extremely significant. The electrical properties of capacitors can be improved after drying and dehumidification, but the consequences of water molecule electrolysis cannot be eradicated. For example, under the high temperature conditions of capacitor operation, water molecules are electrolyzed into hydrogen ions (H+) and hydroxide radicals under the action of an electric field. ions (OH-), causing electrochemical corrosion of the roots. Even after drying and dehumidification, it is impossible to restore the leads.

2.Consequences of silver ion migration

🌖Most of the inorganic dielectric capacitors use silver electrodes. When the semi-sealed capacitors work under high temperature conditions, the water molecules that penetrate into the capacitors generate electrolysis. An oxidation reaction occurs at the anode, and silver ions combine with hydroxide ions to form silver hydroxide; at the cathode, a reduction reaction occurs, and silver hydroxide reacts with hydrogen ions to form silver and water. Due to the electrode reaction, the silver ions of the anode are continuously reduced to the cathode to form discontinuous metallic silver particles, which are connected by the water film and extend to the anode in a tree-like manner. The migration of silver ions not only occurs on the surface of the inorganic medium, but also diffuses into the interior of the inorganic medium, causing an increase in leakage current, and in severe cases, a complete short circuit between the two silver electrodes, resulting in capacitor breakdown.

🌗Ion migration can seriously damage the silver layer on the surface of the positive electrode. Between the lead solder joint and the silver layer on the surface of the electrode, there is silver oxide with semiconductor properties, which increases the equivalent series resistance of the inorganic dielectric capacitor, increases the loss of the metal part, and increases the loss of the capacitor. The tangent value increased significantly.

🌘As the active area of the positive electrode decreases, the capacitance of the capacitor will decrease accordingly. The surface insulation resistance is reduced due to the presence of silver oxide semiconductors on the surface of the dielectric between the two electrodes of the inorganic dielectric capacitor. When the migration of silver ions is serious, a dendritic silver bridge is erected between the two electrodes, which greatly reduces the insulation resistance of the capacitor.

✨To sum up, the migration of silver ions will not only deteriorate the electrical properties of unsealed inorganic dielectric capacitors, but may also cause the dielectric breakdown field strength to decrease, and finally lead to capacitor breakdown.

🌟It is worth mentioning that the failure of silver electrode low-frequency ceramic monolithic capacitors due to the migration of silver ions is much more serious than other types of ceramic dielectric capacitors, due to the one-time firing process and multi-layer laminate structure of this capacitor. During the first baking process of the silver electrode and the ceramic medium, silver participates in the solid-phase reaction on the surface of the ceramic medium, and penetrates into the contact point of the ceramic silver to form an interface layer. If the ceramic medium is not dense enough, the migration of silver ions can not only occur on the surface of the ceramic medium, but also penetrate the ceramic medium layer after water infiltration. When the outer electrodes are coated on both ends of the lamination layer, the silver paste penetrates into the gap, which reduces the insulation resistance of the dielectric surface and shortens the path between the electrodes, which is prone to short-circuit phenomenon when silver ions migrate.

3.Breakdown Mechanism of Ceramic Capacitors under High Humidity Conditions

☀️Breakdown failure is a common and serious problem for semi-hermetic ceramic capacitors operating in high humidity environments. The breakdown phenomenon that occurs can be roughly divided into two types: dielectric breakdown and surface-to-pole breakdown. Dielectric breakdown can be divided into early breakdown and aging breakdown according to the time of occurrence. Early breakdown exposes defects in capacitor dielectric materials and production processes. These defects lead to a significant reduction in the dielectric strength of ceramic dielectrics, so that under the action of an electric field in a high-humidity environment, capacitors may be damaged during the withstand voltage test or in the early stage of operation. Electrical breakdown occurs. Aging breakdown mostly belongs to the category of electrochemical breakdown. Electrolytic aging breakdown of ceramic capacitors has become a fairly common problem due to the migration of silver in ceramic capacitors. Yinqian

🌈The conductive dendrites formed by migration can locally increase the leakage current, which can cause thermal breakdown and cause the capacitor to break or burn. Thermal breakdown occurs mostly in tubular or disc-shaped small porcelain dielectric appliances, because local heating is severe during breakdown, and thinner tube walls or smaller porcelain bodies are easy to burn or break.

⛄️In addition, in the ceramic dielectric mainly composed of titanium dioxide, the reduction reaction of titanium dioxide may also occur under load conditions, so that the titanium ion changes from tetravalent to trivalent. The old ceramic dielectric significantly reduces the dielectric strength of the capacitor, which may cause capacitor shock. Put on. Therefore, the electrolytic breakdown of such ceramic capacitors is more serious than that of ceramic dielectric capacitors without titanium dioxide.

☃️The electric field between the electrodes of the silver ion migration capacitor is seriously distorted, and the surface of the ceramic dielectric is condensed with a water film in a high-humidity environment, which causes the corona discharge voltage on the edge surface of the capacitor to drop significantly, and the phenomenon of flying between the surface electrodes occurs under working conditions. In severe cases, it will lead to the breakdown of the flying solitary between the electrodes on the surface of the capacitor. Surface breakdown is related to factors such as capacitance structure, inter-electrode distance, load voltage, hydrophobicity and moisture permeability of the protective layer. The main reason for the breakdown of the flying solitary between the poles on the edge surface is that the amount of edge left in the dielectric is small. When working in a humid environment, the migration of silver ions and the formation of surface water film make the insulation resistance of the edge surface of the capacitor drop significantly, causing corona discharge and eventually lead to shock. Put on. Especially in high humidity environments. Since it takes a period of time for the generation and development of silver ion migration, in the initial stage of the withstand voltage test, the main failure mode is dielectric breakdown, until after 500h of the test, the main failure mode transitions to the edge-surface inter-pole flying solitary breakdown.

4.Improvements in Electrode Materials

🍭Ceramic capacitors have always used silver electrodes. The migration of silver ions and the consequent accelerated aging of titanium-containing ceramic dielectrics are the main reasons for the failure of ceramic capacitors. Some manufacturers have used nickel electrodes instead of silver electrodes in the production of ceramic capacitors, and electroless nickel plating is used on the ceramic substrate. Since nickel has better chemical stability than silver and has low electrical mobility, the performance and reliability of ceramic capacitors are improved.

🍧Another example is the monolithic low-frequency ceramic dielectric capacitor with silver as the electrode. Since the silver electrode and material are sintered at 900 ℃ for one time, the dense ceramic dielectric cannot be obtained, and there is a large porosity. The flux barium oxide will penetrate into the interior of the porcelain body, and rely on the good infiltration “mutual fusion” ability between barium oxide and silver at high temperature, so that thermal diffusion occurs inside the electrode and the medium, which is the macroscopic “porcelain absorption”. silver” phenomenon. After the silver enters the porcelain body along with the barium oxide, the effective thickness of the medium is greatly reduced, resulting in a reduction in the insulation resistance and reliability of the product. In order to improve the reliability of monolithic capacitors, silver palladium electrodes are used instead of electrodes that usually contain barium oxide, and 1% of 5# glass frit is added to the material formula. It eliminates the thermal diffusion of the metal electrode to the ceramic dielectric layer during the first sintering at high temperature, which can promote the sintering and densification of the ceramic material, so that the performance and reliability of the product are greatly improved. Compared with the original process and dielectric materials, the capacitor’s The reliability is improved by 1 to 2 orders of magnitude.

5.Fracture of laminated ceramic capacitors

🤹The most common failure of laminated ceramic capacitors is fracture, which is determined by the brittleness of the dielectric of laminated ceramic capacitors. Since the laminated ceramic capacitor is directly welded on the circuit board, it is directly subjected to various mechanical stresses from the circuit board, while the leaded ceramic capacitor can absorb the mechanical stress from the circuit board through the pins. Therefore, for laminated ceramic capacitors, the mechanical stress caused by different thermal expansion coefficients or circuit board bending will be the most important factor for the rupture of laminated ceramic capacitors.

6.Fracture Analysis of Laminated Ceramic Capacitors

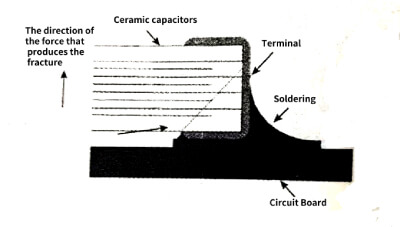

🤹Figure 3.47 shows a schematic diagram of a laminated ceramic capacitor breaking after being subjected to mechanical force.

Figure 3.47

Figure 3.47

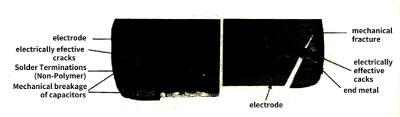

🧸After the laminated ceramic capacitor is mechanically fractured, the electrode insulation spacing at the fracture will be lower than the breakdown voltage, which will lead to the electrical discharge between two or more electrodes and completely damage the laminated ceramic capacitor. The cross-sectional microstructure of a laminated ceramic capacitor with discharge between electrodes after mechanical fracture is shown in Figure 3.48.

Figure 3.48

Figure 3.48

🎸The main methods to prevent the mechanical fracture of laminated ceramic capacitors are: reduce the bending of the circuit board as much as possible, reduce the stress of the ceramic chip capacitor on the circuit board, and reduce the difference between the thermal expansion coefficient of the laminated ceramic capacitor and the circuit board. mechanical stress.

🪕How to reduce the stress of the laminated ceramic capacitor on the circuit board will be described separately below, and will not be repeated here. Reduce the mechanical stress caused by the difference in the thermal expansion coefficient between the laminated ceramic capacitor and the circuit board, which can be alleviated by selecting a capacitor with a small package size. For example, the aluminum-based circuit board should use a package below 1810 as much as possible. It can be solved by the method of multiple parallel connection or by the method of lamination, and it can also be solved by the ceramic capacitor in the form of package with pins.

7. Electrode terminals of laminated ceramic capacitors are melted and showered

🏆When wave soldering the laminated ceramic is the container, it may occur that the electrode tip is melted off by the solder. The main reason is that the wave soldering laminated ceramic capacitors have been in contact with high-temperature solder for a long time. Now the laminated ceramics on the market are divided into containers suitable for reflow soldering process and wave soldering process. If it is suitable for reflow soldering The laminated ceramic capacitors produced by the process are used for wave soldering, and the phenomenon of melting and showering of the electrode terminals of the laminated ceramic capacitors is likely to occur. The time characteristics of the high-temperature solder that the electrode terminals of laminated ceramic capacitors can withstand under different welding processes are described in detail in the applicable precautions for laminated ceramic capacitors, which will not be repeated here.

🍓The way to eliminate it is very simple, that is, when using the wave soldering process, use the laminated ceramic capacitors that conform to the wave soldering process as much as possible, or do not use the wave soldering process as much as possible.